Advantages of Webbing Lashing Systems

- All lashings are individually and uniquely numbered for traceability and safety.

- High Tenacity Polyester webbing has a high resistance to abrasion – much higher than its polypropylene / Nylon equivalent.

- Webbing does not weaken with age.

- Ability to absorb shocks.

- No hidden corrosion – can be easily checked by eye for damage.

- Less risk of damage to the load or to painted/Coated surfaces.

- Supple – can adapt to fit the load easily thereby reducing the chances of damage.

- Easy and quick to use, saving time and thus saving costs.

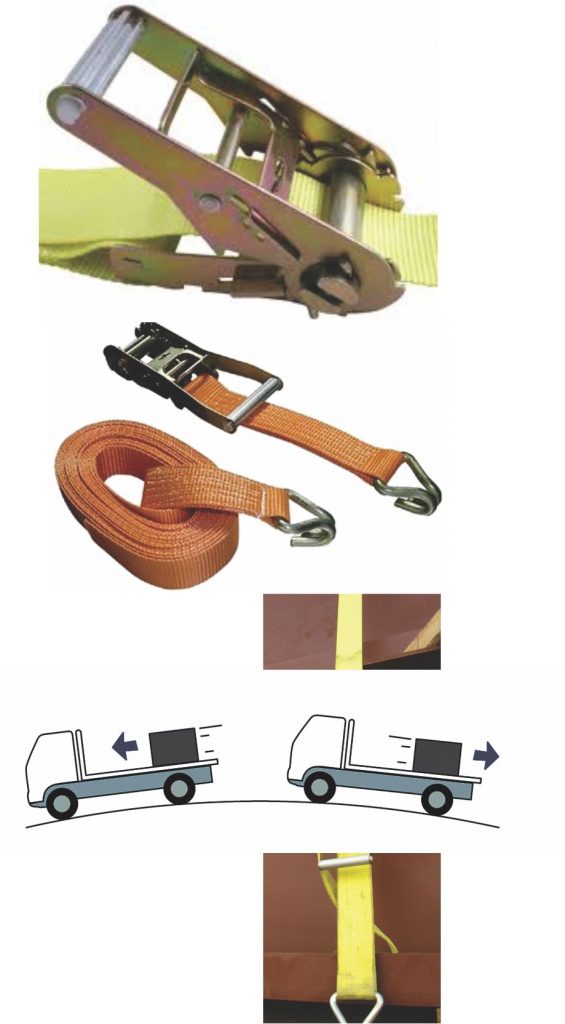

Care and Use of Webbing Lashings:

- Only use webbing lashings manufactured to EN 12195-2:2001

- Only use lashings which are clearly marked with a rated assembly strength and minimum break strength.

- Regularly check the system for cuts and frays in the webbing.

- Never use a bar or lever to tighten the ratchet tensioner.

- Protect the system from sharp edges.

- Keep away from alkalis and strong acids.

- Do not use for lifting.

- Do not tie knots in the webbing to shorten it.

- When the tensioner is a ratchet, ensure that there have been at least 2 complete turns of the spreader bars after threading.